SEALING AIR FAN COAL MILL

2020-04-20T04:04:45+00:00

How accurate primary airflow measurements improve

May 15, 2006 The net effects of leakage flows from, and seal airflow into, mills and pulverizers can be significant (see the "Total coal pipe flows May 26, 2020 How Mills work in a thermal power plantBall and tube Mills workingPulverisers in thermal power plantBall and Tube Mills working Part 1/ What is Seal Air Fan CFW Fans supplies reliable seal air blowers to the power generation industry Contact us for more information on +27 21 931 8331 +27 Home; Products Seal air blowers SEAL AIR BLOWERS CFW Fans

CNU Sealing air system of mediumspeed

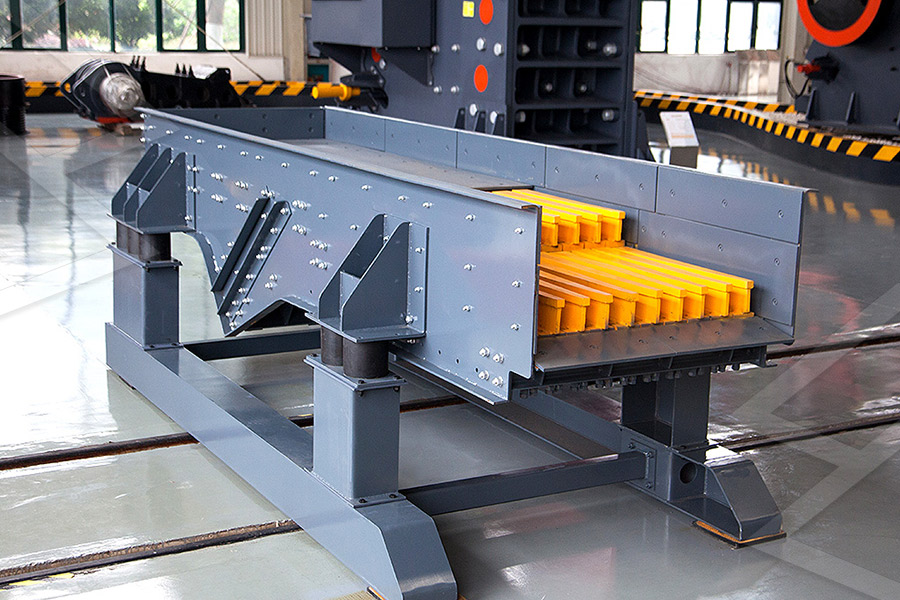

A sealing air system of a mediumspeed coal mill comprises a seal fan, a mediumspeed coal mill and a sealed pipeline, wherein two ends of the sealed pipeline are Most milling operations focus on four mechanisms that occur in a coal mill system: 1 Comminution (size reduction); 2 Drying; 3 Transport of material; 4 Classification Coal Mill an overview ScienceDirect TopicsJan 1, 2022 The seal air is supplied from one seal air blower to each position of several coal mills at a target power station An imbalance in its flowrate can lead to coal mill Measurement of seal air flowrate at five coal mill locations

Primary air fan for boiler in power plant Geckointech

Primary air plays an important role in boiler combustion in coal fired power plants It supplies oxygen for burning and heat for fuel drying, also it conveys pulverized coal to Answer / smondal seal fan is used in coal mill to seal the mill from bearing so that no dust particle able to enter into bearing zone this fan takes suction from primary air fan why seal air fan is used and where it is used and where isAnswer (1 of 5): First of all why we are using Seal Air As the name itself suggest that it should be used for sealing something from this we came to know it is maintaining a seal to protect something The pulverizer mill is What if we run a bowl mill without sealing the air for a

CDC Mining Feature Coal Mine Explosion Prevention NIOSH

Oct 26, 2016 Mining Feature: Coal Mine Explosion Prevention There are two main types of coalmine explosions: methane and coal dust Methane explosions occur when a buildup of methane gas contacts a heat source and there is not enough air to dilute the gas level below its explosion point Likewise, fine particles of coal dust in the right concentration Jan 1, 2015 Each mill is equipped with a sealing fan; sealing air is used for mill sealing to prevent coal powder leaking 3 Theoretical formula for the online calculation of coal moisture Because coal is fed into the mill by a conveyor belt, the coal heats up and dries during grinding and thus incurs moisture lossSoft sensing of coal moisture ScienceDirectAug 7, 2016 • MILL AIR FLOW DEPENDS ON FEEDER SPEED: • FOR FEED RATE 033% AIR FLOW WILL BE 276 TPH FOR FEED RATE 33%100% AIR FLOW WILL BE 276TPH TO 36 TPH LINEAR • IF Pulverized coal fired boiler startup procedure

Modeling of Coal Mill System Used for Fault

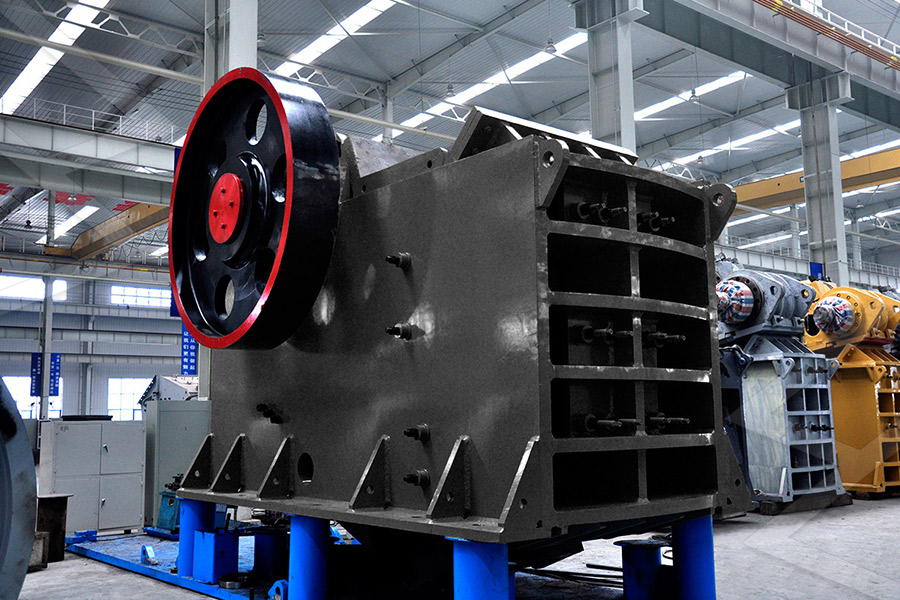

Apr 7, 2020 The mediumspeed coal mill system is mainly composed of raw coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and cold air regulating valves The coal feeder transports the raw coal from Maintain about (−) 40 Pa of furnace draft throughout the clean air flow test; v Start the seal air fan of the associated pulverizer under test; vi Both approaches utilize the same process of fuel handling, including feeder systems to guide coal from the bunker, the mill to make fine coal powder, and the cyclone separator Coal Pulverizers an overview ScienceDirect TopicsA sealing air system of a mediumspeed coal mill comprises a seal fan, a mediumspeed coal mill and a sealed pipeline, wherein two ends of the sealed pipeline are communicated with the seal fan and the mediumspeed coal mill respectively, and the sealed pipeline is formed by sequentially connecting an upward rectangular pipe, a horizontal rectangular CNU Sealing air system of mediumspeed coal mill

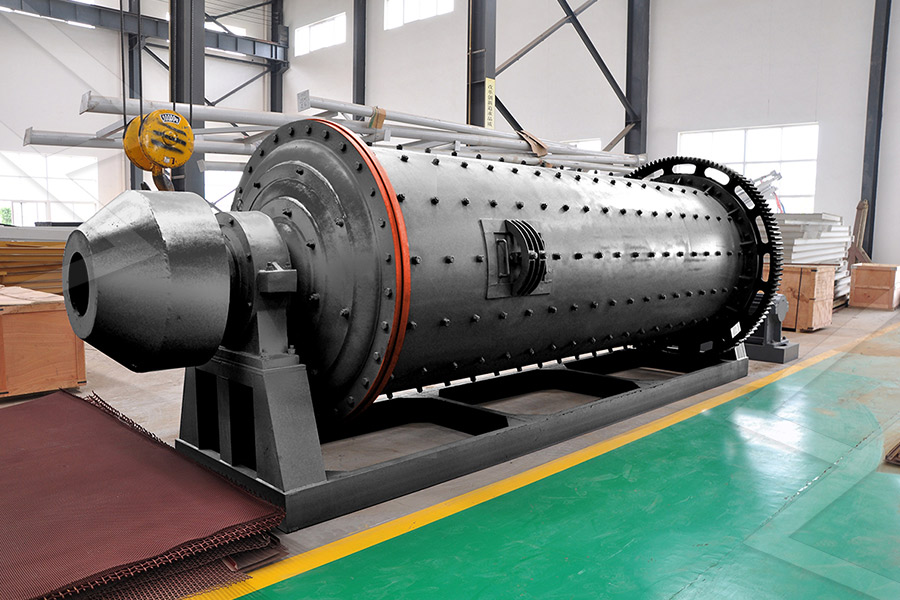

Pulverizer Wikipedia

Maintaining the coal level in the mill offers a builtin capacity cushion of pulverized fuel to take care of short interruptions in the raw coal circuit The mill is pressurized and the airtightness is ensured by plenum chambers around the rotating trunnion filled with pressurized seal air Bleeding seal air from plenum chamber to the mill The four most common coal pulverizers types are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the Coal Pulverizer – Power Plant Pall CorporationMining Ventilation Not only does Clarage offer a complete line of axial flow and centrifugal fans for mine ventilation applications, we can also provide the design of the connecting duct from the mine shaft collar to the fan inlet connection Improper duct design will reduce fan performance and add unnecessary pressure loss to the system Both Mining Ventilation Clarage

Mill Inerting Systems Presentation to the ASBCUG

Jun 7, 2018 Damage repair cost (Primary air inlet ducts, PA fans, mill internals, feeders, etc) Derates, forced outage, shut down air to fuel ratio us too low for preignition of coal or below the explosive or combustible range inside the coal mill Coal and air is being actively mixed inside the mill and localized areas of high air to fuel ratioThe utility model discloses a sealing air inlet device of a coal mill, comprising a coal mill, wherein the coal mill is internally provided with a driving disc which is externally provided with a sealing cavity, and the sealing cavity is communicated with a seal fan through a pipeline which is internally provided with a fan adjusting control valve, the pipeline at the CNU Sealing air inlet device of coal mill Google inner cylinder of the fan by creating a positive differential pressure in the inner cylinder At the same time the heating element in the seal air equipment prevents the seal air from causing condensation The equipment The seal air system is a redundant system consisting of two parallel centrifugal fans working one at a time (the other as back Howden Axial Fan Retro t Solution Seal air

Modeling of Coal Mill System Used for Fault Simulation

Apr 7, 2020 same time, partial cold primary air is pressurized by the sealing fan to prevent the leakage of coal powder Inside the coal mill, the grinding part is composed of a groove type grinding plate andMar 1, 2007 Thermal power plants mostly employ bowl mills to crush coal which in turn is used in the boiler for generating steam These bowl mills encounter failures with respect to grinding components and/or Causes of pulverizedcoal leakage from a race pulverizer and its seal Nov 16, 2012 41Drying The coal that is passing through a pulverizer is entrained by the use of hot air usually from the air heater During the pulverization process the surface area of the coal particles increases Coal mill pulverizer in thermal power plants

Soft sensing of coal moisture ScienceDirect

Jan 1, 2015 Each mill is equipped with a sealing fan; sealing air is used for mill sealing to prevent coal powder leaking 3 Theoretical formula for the online calculation of coal moisture Because coal is fed into the mill by a conveyor belt, the coal heats up and dries during grinding and thus incurs moisture lossApr 7, 2020 The mediumspeed coal mill system is mainly composed of raw coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and cold air regulating valves The coal feeder transports the raw coal from Modeling of Coal Mill System Used for Fault Maintain about (−) 40 Pa of furnace draft throughout the clean air flow test; v Start the seal air fan of the associated pulverizer under test; vi Both approaches utilize the same process of fuel handling, including feeder systems to guide coal from the bunker, the mill to make fine coal powder, and the cyclone separator Coal Pulverizers an overview ScienceDirect Topics

CNU Sealing air system of mediumspeed coal mill

A sealing air system of a mediumspeed coal mill comprises a seal fan, a mediumspeed coal mill and a sealed pipeline, wherein two ends of the sealed pipeline are communicated with the seal fan and the mediumspeed coal mill respectively, and the sealed pipeline is formed by sequentially connecting an upward rectangular pipe, a horizontal rectangular Aug 7, 2016 • BOTH SEAL AIR FANS RUNNING AND SEAL AIR TO COLD PA DP NOT LOW AND COMMAND GIVEN FOR STOPPING PROTECTION SrN DESCRIPTION VALUES TIMER (SEC)ALARM Pulverized coal fired boiler startup procedureApr 7, 2020 In order to obtain massive fault sample data effectively, based on the analysis of primary air system, grinding mechanism and energy conversion process, a dynamic model of the coal millModeling of Coal Mill System Used for Fault Simulation

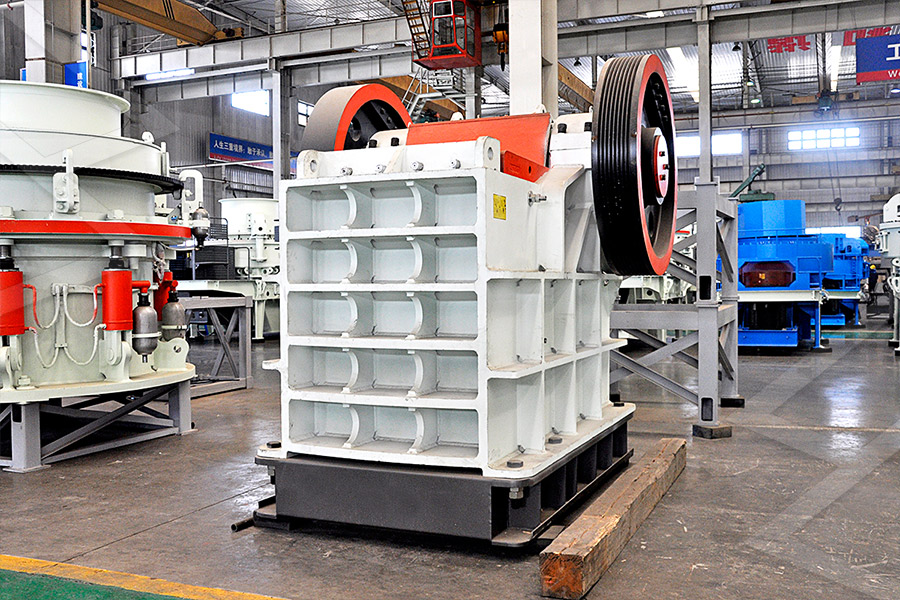

Coal Mill an overview ScienceDirect Topics

Most milling operations focus on four mechanisms that occur in a coal mill system: 1 Comminution (size reduction); 2 Drying; 3 Transport of material; 4 Classification Failure to understand all four and their interrelationship is most often the The four most common coal pulverizers types are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the Coal Pulverizer – Power Plant Pall CorporationThe seal air fan provides the opposite pressure to avoid the leakage of pulverized coal 125 Classifier Vung Ang I Thermal Power Plant 2600MW Coal Fired Project the seam valve and primary air gate are closed 927 The main motor of the coal mill is shut down 928 The seal air fan is shut down 929 The stop valve of pulverized coal is VA1 NHI 00100 M M1C MAN 0003 Rev1 Coal Mill Operation Manual

seal air fan is mainly used to evaporate dust particles in coal mill

Answer Posted / swapnil nborkar seal air fan is mainly used to evaporate dust particles in coal mill that is for sealing purpose The suction of seal air fan is taken from Primary air Line Is This Answer Correct ?It is opened before every start of elevation and after shutdown of elevation for purging the coal pipes 18) SEAL AIR FANS : As per design principle of ball mill, the coal air ratio coming out from the mill is always constant Technical FeedbackMar 1, 2007 Through the modification, the air and pulverizedcoal leakage phenomena have been effectively eliminated with the working environment being improved and operation costeffectiveness enhancedCauses of pulverizedcoal leakage from a race pulverizer and its seal

Mill Inerting Systems Presentation to the ASBCUG

Jun 7, 2018 Damage repair cost (Primary air inlet ducts, PA fans, mill internals, feeders, etc) Derates, forced outage, shut down air to fuel ratio us too low for preignition of coal or below the explosive or combustible range inside the coal mill Coal and air is being actively mixed inside the mill and localized areas of high air to fuel ratioApr 2, 2020 mill The air enters the pulverizer t hrough nozzles in the air motorized seal air fan ope rating in conjunction with the mill, Coal mill motor power (kW) 0 4171 4548 4390 Analysis of the Coal Milling Operations to the Boiler Parameters